Modifier for Biodegradable Plastic

CARBODILITETM C-768CARBODILITEC-768 is a new product in the CARBODILITE series that has the following effects. This is a new product that no gas and has a particularly good cost-effectiveness,Can significantly increase the hydrolysis resistance of biodegradable resins containing ester bonds

- Effect

keyword

keywordCrosslinking effect(reacting with hydroxyl and carboxyl groups, ncreasing strength,chain

elongation, enhancing molecular weight,compatibilizer)Viscosity adjustment (to prevent drawdown and ease of processing)

Acid supplementation (improving hydrolysis resistance and increasing product service life)Nissinbo Chemical

Patented technology

owned - Use to

Shopping bags, agricultural film, extruded products, injection molded products,masterbatch products, etc

Examples of biodegradable plastics : PBAT,PLA,PBS,PBSA,PHA - Character

Product name CARBODILITE™ C-768 Appearance Light yellow powder

Average particle size 1000 μ Below m (representing value) Softening temperature approximately 60 Features Polymeric - Gas generation

Processed film

Incidental odor ※1Harmful gases

during processing※2

(Isocyanate)heat resistance

Td5(℃) ※3No additives nil nil - C-768 nil almost none 260 Products from other

companies

(Monome rcarbodiimide)yes spawn 200 ※1:Functional examination resin:PBAT Mixing conditions:160℃

※2:Test method: GC-MS analysis of harmful gases generated by samples with 1wt% modifier added Resin: PBT Mixing condition: 250 ℃

※3:Temperature at 5% weight reduction Temperature rise condition: 5 ℃/min Our measured values

The terminal product using C-768 will not produce odor.

Due to the effective suppression of the gas generated during processing, it can be used with confiden.

- Melt viscositybase resin:PBAT/PLA=7/3

No additives 170~180℃ C-768 180~200℃ Products from other companies 170~180℃ Adding C-768 has the effect of increasing viscosity.

As shown in the table on the right, by increasing the processing temperature, C-768 can be processed under the same conditions as other company products.

※Can be used in conjunction with other company products.

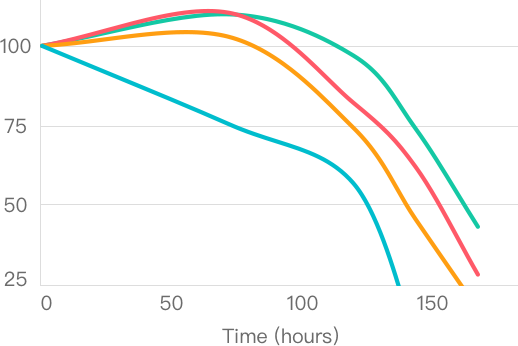

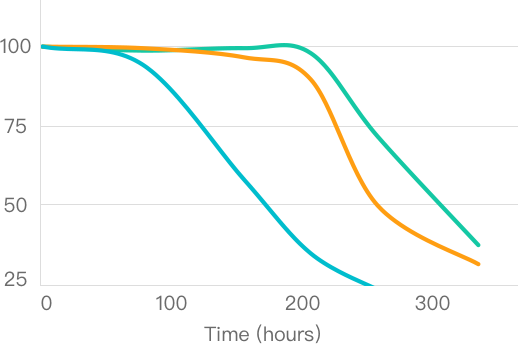

- Hydrolysis ResistanceHumidity and heat resistance test(80℃×95%RH)

Elongation at break retention (%) PBAT

Tensile strength retention (%) PBS

By addingC-768,The hydrolysis resistance has been significantly improved.No additivesProducts from other companies0.5%C768 0.5%C-768 0.25%+Products from other companies0.25%

By addingC-768,The hydrolysis resistance has been significantly improved.No additivesProducts from other companies0.5%C768 0.5%C-768 0.25%+Products from other companies0.25%